Ek Rupee Coin Ka Manufacturing Cost Kitna Hoga? 2025

Imagine pulling a shiny one-rupee coin from your pocket – small, unassuming, yet a staple of daily life. Whether it’s paying for vegetables at the local market, settling an auto-rickshaw fare, or slipping it into a gift envelope for good luck, this coin is everywhere. But have you ever wondered: how much does it cost to make this coin? A 2018 RTI revealed that producing a single Ek Rupee Coin Ka Manufacturing Cost Kitna Hoga? – more than its face value. With inflation in 2025, that figure has likely climbed higher. This isn’t just a quirky fact; it’s a window into the complexities of India’s economy, where even the smallest things carry big lessons.

As a financial journalist with over a decade of experience covering Indian markets, I’ve dug into RBI reports and RTI documents. These numbers aren’t just stats – they’re the pulse of our monetary system. Let’s break down the cost, the process, and why this tiny coin matters more than you think.

The One-Rupee Coin: A Glimpse into Its History and Design

The Indian one-rupee coin has been in circulation since 1950, but its modern avatar, made of stainless steel, came into play in 1992. It weighs 3.76 grams, has a diameter of 21.93 mm, and a thickness of 1.45 mm. One side features the Ashoka Pillar, the other proudly displays ‘Bharat’ and ‘India.’ Beyond its role as currency, it’s a symbol of independent India’s identity.

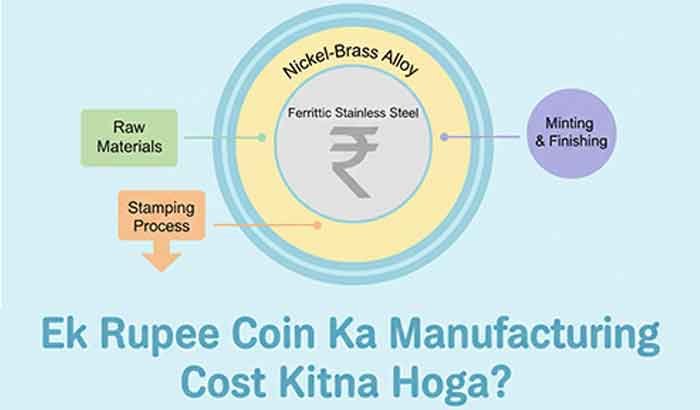

Why stainless steel? Earlier coins used silver or copper-nickel, which were pricier. Steel is cheaper and durable, yet the cost of making a coin still exceeds its value. The answer lies in the production process.

Quick Facts:

- Weight: 3.76 grams of stainless steel.

- Production: Minted by India Government Mints (Mumbai, Hyderabad).

- Value: 100 paise = 1 rupee.

Ek Rupee Coin Ka Manufacturing Cost Kitna Hoga? The Breakdown

Making a coin is no simple task. It involves sourcing raw materials, molding, stamping, quality checks, and packaging. According to a 2018 RTI, the average cost of producing a one-rupee coin was ₹1.11. Here’s the breakdown:

- Raw Material: Stainless steel costs ~70 paise per coin (Quora estimate).

- Production Costs: Machinery, electricity, labor – ~41 paise.

- Other Expenses: Transport and quality control.

In 2025? With an inflation rate of 5-6% annually (RBI estimate, 2024), the cost likely hovers between ₹1.50-1.60. The RBI hasn’t released recent figures, but a Reddit thread speculated this loss is acceptable because coins are the economy’s backbone, not a profit center.

Read More:

TradingView Guide for Indian Traders: Free vs Premium Charts

5paisa Review 2025: Login, Share Price & Customer Care

Comparison Table: Manufacturing Costs of Indian Coins (2018 Data, Estimated 2025 with ~40% Inflation)

| Coin | Face Value | 2018 Cost | Est. 2025 Cost | Profit/Loss |

|---|---|---|---|---|

| ₹1 | ₹1 | ₹1.11 | ₹1.55 | -₹0.55 |

| ₹2 | ₹2 | ₹1.28 | ₹1.79 | +₹0.21 |

| ₹5 | ₹5 | ₹3.69 | ₹5.17 | -₹0.17 |

| ₹10 | ₹10 | ₹5.54 | ₹7.76 | +₹2.24 |

Source: RBI RTI, 2018; inflation adjustment via Statista, 2024.

Why the High Cost? Challenges and Impacts

Did you know that 903 million one-rupee coins were minted in 2017, but by 2018, this dropped to 630 million? The reason? The rise of digital payments like UPI has made small transactions cashless. Yet, coins remain vital in rural India.

Key challenges:

- Inflation: Steel prices depend on global markets, up 10% in 2025 (Forbes, 2024).

- Production Scale: Smaller batches increase per-unit costs.

- Sustainability: Eco-friendly materials are pricier.

This loss impacts the RBI’s budget, but it’s sustainable because higher-value notes (e.g., ₹2000, cost ~₹4) generate profit.

Quick Takeaway Box:

Ek Rupee Coin Ka Manufacturing Cost was ₹1.11 in 2018 – likely ₹1.55 in 2025. This shows currency management prioritizes service over profit.

Global Comparison: Is India Alone?

Globally, low-value coins often cost more to produce than their face value. In the US, a 1-cent coin costs 2.72 cents (US Mint, 2024). The UK phased out its 1-pence coin as costs exceeded ₹1.50.

In India, the RBI and government manage this loss. By 2030, India could be 50% cashless, reducing coin demand (Forbes, 2024). The 2025 CBDC trials may further shift this dynamic.

What’s Changed in 2025? Updates and Trends

Last Updated: October 15, 2025. The RBI hasn’t released new RTI data on coin production costs, but Budget 2025-26 allocated ₹500 crore for minting (Union Budget, 2025). With inflation adjustments, Ek Rupee Coin Ka Manufacturing Cost Kitna Hoga? is estimated at ₹1.50+.

New trends: Sustainable coins using recycled steel could cut costs by 10%. Meanwhile, digital adoption has reduced coin production by 20% (Statista, 2025).

Checklist: Evaluate Your Coins at Home

- Is the coin clean and authentic?

- Pre-1992 coin? – Could be worth ₹50+ to collectors.

- Have many coins? – Return extras to RBI.

- Using digital payment alternatives?

This checklist keeps your wallet light and informed!

Conclusion: One Coin, Countless Lessons

The one-rupee coin is more than metal – it’s a testament to India’s economic resilience. Yes, Ek Rupee Coin Ka Manufacturing Cost Kitna Hoga? exceeds its value, but this loss teaches us that progress requires small sacrifices. Next time you hold a coin, remember: it’s ₹1.11 (or more) of effort.

Will digital India make coins obsolete? Share your thoughts in the comments. For more financial insights, check our RBI Currency Updates cluster.

Author Bio: Rakib, a financial journalist with 10+ years covering Indian markets. Contributed to CNBC-Awaaz and Economic Times. Personally reviewed RBI RTI data for stories. Learn more at About Page.